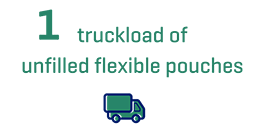

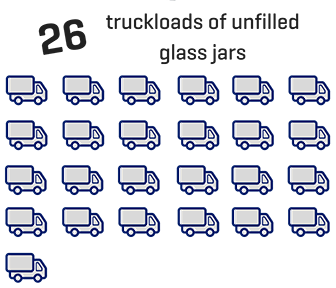

BioFlex™ flexible packaging has sustainability benefits beyond its clean-energy end-of-life solution. Flexible packaging generally uses fewer resources to create, transport, and dispose of compared to other forms of packaging.

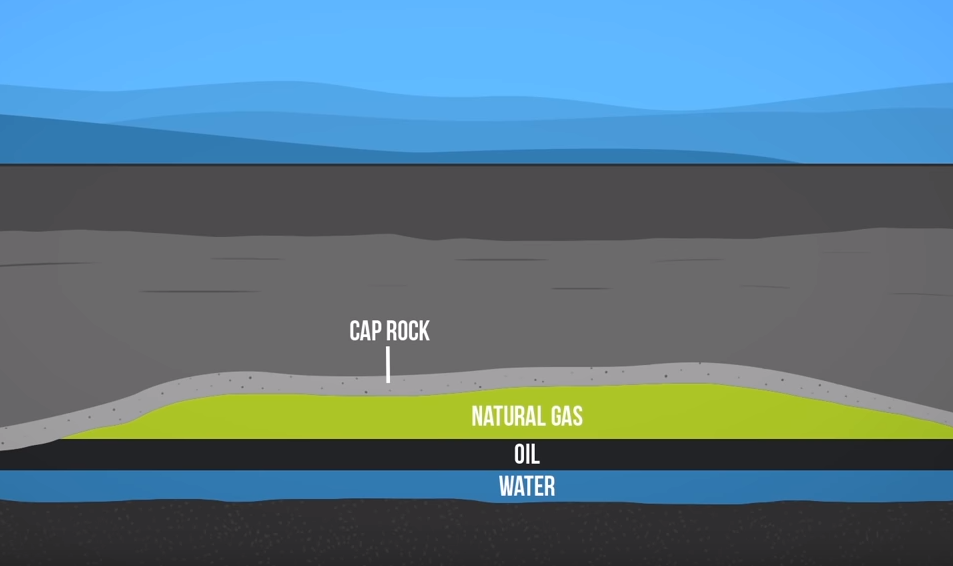

Also, unlike conventional flexible packaging, at the end of its life your packaging can be converted to clean energy*. This energy can be used to offset fossil fuels to heat homes or provide energy to the grid.

**BioFlex™ has been shown to produce biogases 22 times faster than conventional plastic in the ideal conditions of an anaerobic digestor landfill over the course of 2.13 years, using the ASTM D5511-12 test. When disposed of in a landfill with modern biogas capture technologies, this energy can be harnessed as a source of renewable energy. Such a facility may not exist in your area.