What Can I Do?

Flexible plastics are one of the most efficient ways to package foods.

- They require very little material to create oxygen, moisture barrier, and physical protection needed to preserve food.

- Because of its light weight and low volume, they are easy to transport when compared to other packaging types.

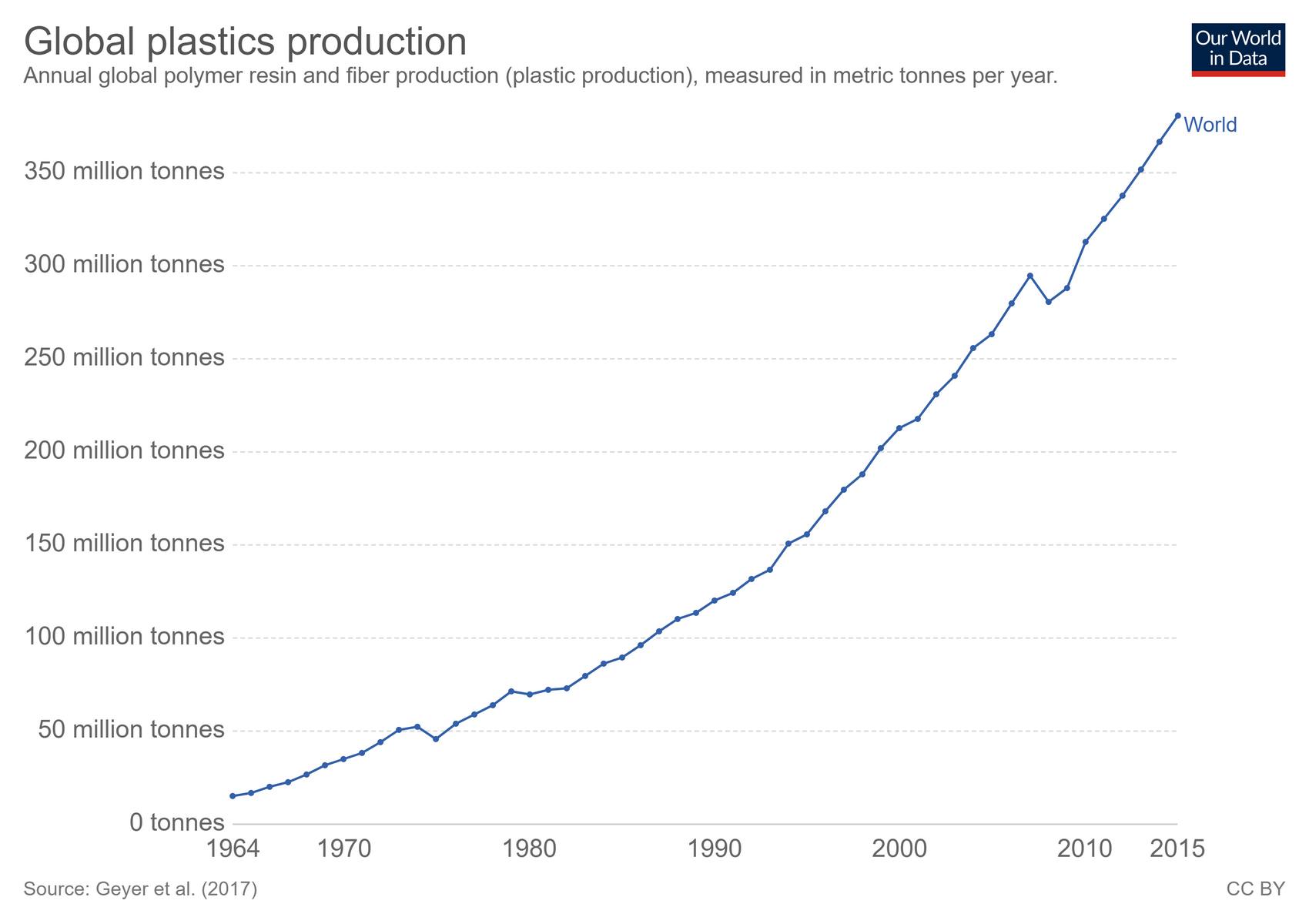

Why is plastic consumption increasing?

- It’s because they are typically single-use which means that the raw materials used to produce them will end up being trapped in a landfill when the package reaches its end-of-life cycle.

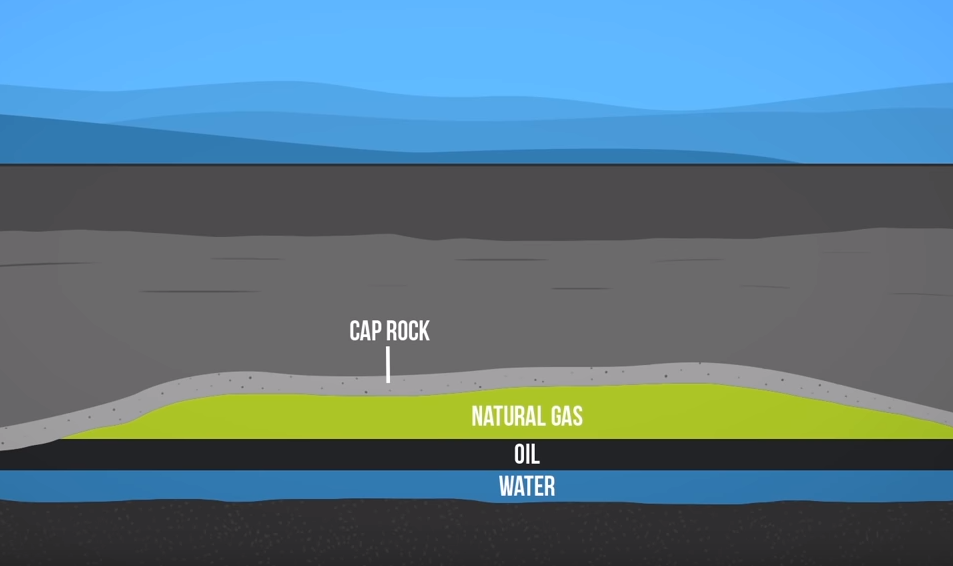

BioFlex™ is packaging that is intended to be discarded because it can increase biogas production in a modern landfill*. Biogas in turn creates clean energy.

*BioFlex™ has been shown to produce biogases 22 times faster than conventional plastic in the ideal conditions of an anaerobic digestor landfill over the course of 2.13 years, using the ASTM D5511-12 test. When disposed of in a landfill with modern biogas capture technologies, this energy can be harnessed as a source of renewable energy. Such a facility may not exist in your area.